Company Background

SED is a ISO 9001:2015 Certified Pakistan based firm providing Energy conservation Solutions, Mechanical Fabrications and Erectors to the Sugar and Allied Industries since 2004.

SED has a specialized team of Engineers for manufacturing, fabrication, installation and commissioning of high tech equipment designed to improve energy efficiency of the Industry. Our workshop located in Karachi is fully equipped and capable of providing fabrication and installation of machinery, vessels, Steel Structure and Steel piping.

Today after 17 years of successful operations. SED is taking a giant leap by changing its Identity and Management Structure. SED was previously known as Spray Engineering Devices, in order to serve a broader range including environment friendly products and services, SED is renamed as Sustainable Environment Developers.

- Research & Development (R&D)

- Process & Project Management

- Instrumentation & Automation Division

- Plant Engineering / Production Division

- Trouble Shooting & Servicing

SED teams are strategically located in various parts of the country to provide quick response to the esteemed customers.

We Started | 2005

We Started offering Automated Condensing System to the sugar industry that enabled the factories to reduce 40% to 50% power consumption at Injection station. The equipment became popular and the install base grew rapidly over the next 10 years.

Energy Efficency Scheme | 2008

First time introduced energy efficient process house equipment in Pakistan to bring down the steam % cane from an average of 55% to 40%. Introduced Falling Film Evaporators, Molasses Conditioners, Direct Contact Juice Heaters, Condensate Flash Cigars, Hot water Radiator Sugar dryers etc. to help the industry in saving significant quantities of bagasse.

Re-Design & Engineering | 2017

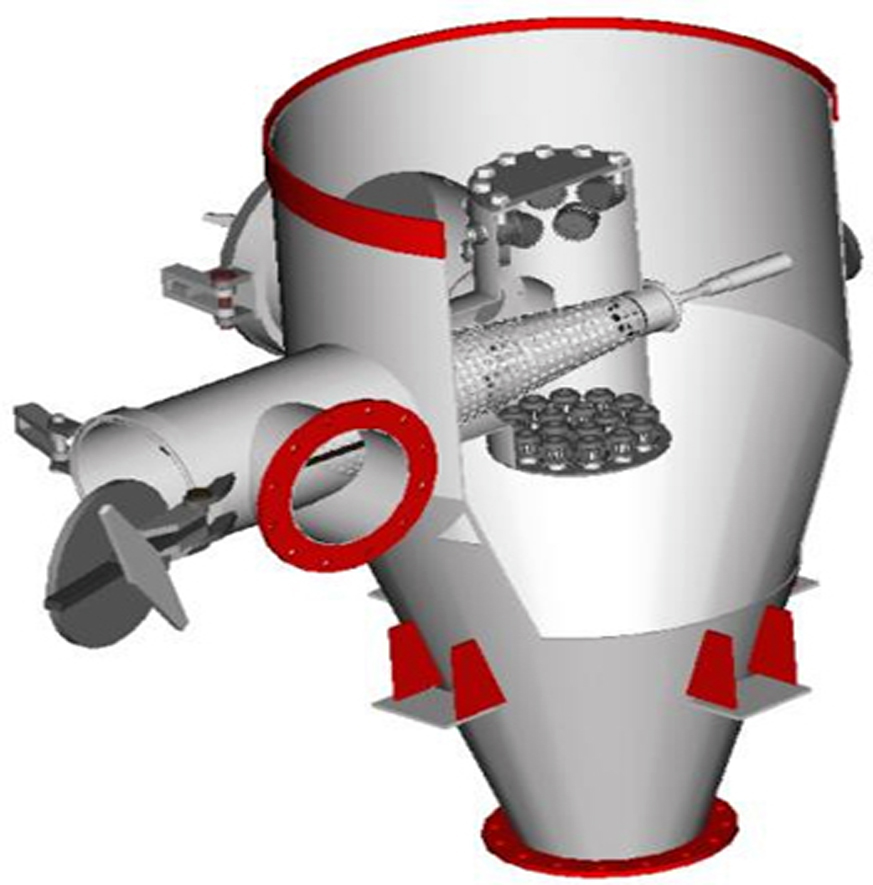

Complete re-design and engineering of an existing sugar plant. Increased the capacity from 4500 TCD to 8000 TCD with steam Consumption of 35%. First time introduced Spray Continuous Pan for low temperature boiling with fully automated operation.

Spray Continuous Pan | 2022

Manufactured and Installed first of its kind Spray Continuous Pan on A Massecuite sufficient for crushing of 12000 TCD. The 42 meter tall, state-of-the-art equipment can operate at 90°C vapors with improved crystallization rate and molasses exhaustion. The tobacco Barn Automation System named Tradomation was installed at 28 Locations for a commercial trial. Tradomation helps in reducing wood consumption and improves tobacco quality. Thus helping farmers getting better returns and simultaneously reducing the environmental impact.

Services

Check our Services

Research & Development

SED is distinguished by a strong focus on needs of the industry. Striving to meet increasingly complex process modifications as well as offering proven and reliable solutions. Our continuous investment in research and development enables us to deliver standard setting solutions across the industry.

Instrumation & Automation

Our instrumentation and automation wing is fully responsible for maintaining maximum efficiency of the equipment / process. We provide services like application software development; detailed automation project planning, engineering & execution; design and supply of electrical & automation systems; instrument selection, procurement, testing, inspection & maintenance etc.

Plant Engineering & Production

SED Project Engineering / Production Division offers expertise in the design and manufacturing of state of the art engineering systems involving a range of technologies & innovations with high precision support structures & Optical systems & Precision mechanisms achieved by efforts of Research & Development Team.

Nozzles & Valves

SED manufacturing inhouse all type of Nozzles like JET, DO, SS Cap Etc. and also provide branded Valves with actuators for better performance.

Servicing & Trouble Shooting

SED has an excellent trouble shooting and servicing division, which benefits for our customers are enhanced with availability of higher efficiency and safety, and reliable assistance with all problems, including maintenance and repair

24/7 Season Support

Season Support available both onsite & online 24x7 offers a complete and extensive after-sales service, maintained throughout the life cycle of our installed machinery and equipment

Call To Action

Support available both onsite & online 24x7 offers a complete and extensive after-sales service, maintained throughout the life cycle of our

installed machinery and equipment

SED | Why Choose Us

SED is an Engineering Company, specifically focused on designing / redesigning and engineering of process & equipment along with automation ensuring highest energy efficiencies. We offer integrated, cost effected solution for Sugar and other process industries.

Happy Clients

Projects Completed

Years of experience

Awards

Team

Check our Team

Saad Masud

Chief Executive Officer

Farrukh Humayun

General Manager

Khalid Hanif

Industrial Process Consultant

Bilal Majid

Electrical & Autoamtion ConsultantContact

Contact Us

Location:

B-144, Block-11, Gulistan-e-Johar, Karachi, Pakistan

Email:

contact@sedl.pk

Call:

+92 300 0342655 | 0300 0342646